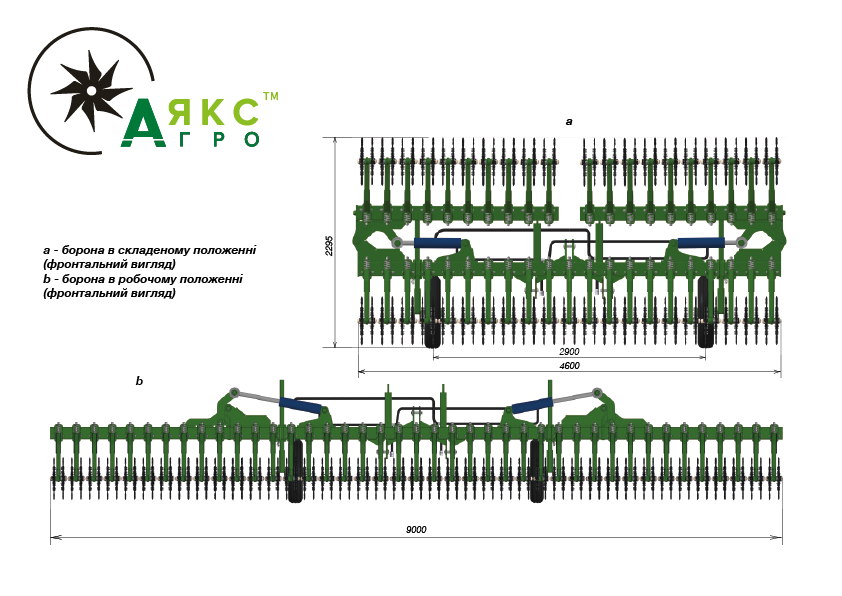

Rotary Harrow 9m Premium (Hitch-mounted)

Manufacturer's warranty on main structural elements - up to 7 years.

Equipment customization for customer needs.

Online and onsite assistance in the equipment launch.

After-sales support and best prices for consumable parts from original manufacturer.

€16785 €14000

Contact

*The price is indicated excluding VAT.

Purpose

Principle of Operation

Technical Specifications

| Characteristic | Value |

|---|---|

| Working speed, km/h | 15-20 |

| Working width, m | 8.8 |

| Performance, ha/cm | Up to 150 |

| Working depth, cm | 3-6 |

| Weight, kg | 2450 |

| Weight of one section, kg | 36 |

| Personnel required | 1 (tractor driver) |

| Hitching type | Suspended |

| Dimensions in working position (m) | Value |

|---|---|

| Width | 8.8 |

| Length | 1.98 |

| Height | 1.565 |

| Dimensions in transport position (m) | Value |

|---|---|

| Width | 4.615 |

| Length | 1.98 |

| Height | 2.45 |

Video Overview

Design Advantages

- The main beam is made from a solid-drawn square tube 150x150, with a wall thickness of 8 mm.

- Cast knives with a blade (steel 45L, heat-treated), for injecting nitrogen into the soil and protecting the crops from damage.

- Use of sealed, maintenance-free bearings of the "SKF" brand, Italy (Warranty: 1 year or 2000 hectares).

- Sections - welded with a thickness of 4 mm, reinforced with side overlays of 5 mm from the center to the frame bracket. (Warranty: 3 years).

- Use of silent blocks at the section attachment point to the main frame, to protect against premature failure of the stand due to vibration. (Warranty: 7 years or 30,000 hectares).

- Hydraulic system with an increased safety margin. (Warranty: 1 year).